The Popularity of Canned Seafood

Canned fish and seafood are popular for several reasons. First and foremost, they offer a convenient and quick way to eat. Canned foods can be stored for a long time without refrigeration, making them an ideal choice in emergencies and for those who don’t have time to cook. Secondly, canned fish and seafood are often high in nutritional value, including rich proteins, Omega-3 fatty acids, and a variety of vitamins and minerals, making them a healthy dietary choice.

Additionally, the diversity of canned food products is a significant factor. There is a wide variety of canned fish and seafood products available in the market, such as tuna, sardines, mackerel, and crab, catering to different tastes and needs. They can be eaten directly or used as ingredients in other dishes to enhance flavor and nutrition.

Lastly, the affordability of canned fish and seafood is a key factor. Compared to fresh seafood, they are generally more budget-friendly, allowing more people to enjoy the delicious taste and nutritional benefits of seafood. Thus, whether it’s for convenience, nutrition, variety, or cost, canned fish and seafood have become a staple in many households.

Tin Cans as the Principle Packaging for Canned Seafood

The tin cans used for canned fish and seafood are an interesting topic in themselves. Firstly, these cans are mostly made of metal, typically steel or aluminum. These materials are not only durable but also effectively block air and light, helping to preserve the freshness and nutritional content of the food. The metal cans are specially treated with coatings or linings to prevent direct contact between the metal and the food, thereby avoiding chemical reactions or a metallic taste.

Secondly, to ensure the safety and hygiene of the food, these cans undergo thorough sterilization before sealing. This process not only kills potential microbes but also helps extend the shelf life of the food. Additionally, the design of the cans is usually optimized for storage and transport efficiency, with their shapes and sizes meticulously planned for maximum space efficiency.

An important aspect is the environmental consideration. With increasing awareness of sustainable development and environmental protection, many can manufacturers are striving to use more recyclable and eco-friendly materials. This means that, in addition to convenience and practicality, can packaging is also evolving to reduce its environmental impact.

Overall, the cans used for canned fish and seafood are not just an essential part of food preservation technology but also reflect considerations of food safety, storage efficiency, and environmental consciousness.

Canning and Seaming of Canned Seafood

Canning is a centuries-old technique that has been refined over time to become a cornerstone of food preservation. At the heart of this process is can seaming, a critical step that ensures the safety, longevity, and quality of canned products. Can seaming is the process of hermetically sealing a can after it has been filled with food. This sealing is crucial as it protects the food from external contaminants, preserves its nutritional value, and extends its shelf life. The process is intricate and requires precision to ensure that the seal is both airtight and secure.

Steps in the Can Seaming Process

- Preparation of Can and Lid: The process begins with the preparation of the can and its lid. Cans are typically made from metals such as tinplate or aluminum, offering durability and protection against environmental factors. The lids are designed with a curled edge to facilitate the seaming process.

- Filling the Can: The can is filled with the product, which could be anything from fruits and vegetables to fish and meat. In some cases, additional substances like brine or oil are added.

- Exhausting: This step involves removing air from the can to prevent oxidation and spoilage of the food. Typically, this is achieved by heating the can, causing the contents to expand and push out the air.

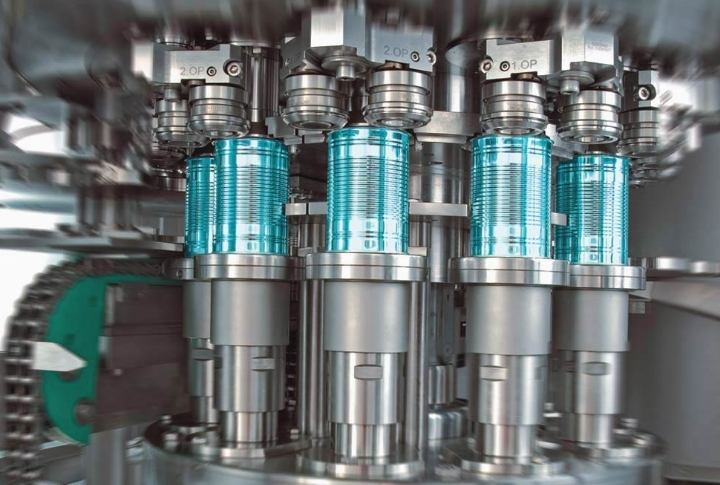

- Seaming: The crucial step of seaming involves a specialized machine that joins the can and its lid. The machine rolls and crimps the edges of the can and lid together, forming a tight, hermetic seal. This step usually involves multiple stages of rolling to ensure a complete seal.

- Sterilization: Post-seaming, the cans undergo sterilization, usually in a retort or autoclave. This process destroys any microorganisms and ensures the food’s safety and longevity.

- Cooling and Drying: After sterilization, the cans are cooled to stop the cooking process, thereby preserving the food’s texture and flavor. They are then dried to prevent rust

What are the Machines Used for Automatic Can Seaming?

Automatic can seaming machines play a pivotal role in the canning industry, especially in large-scale production environments. These machines are designed to seal cans quickly and efficiently, ensuring a tight and reliable seal. Here are some types of machines commonly used for automatic can seaming:

- Rotary Can Seamers: These machines are often used for high-speed seaming. They feature multiple seaming stations that rotate around a central axis. As the can moves through each station, the seaming operation is performed in stages, ensuring a high-quality seal.

- Single Head Seamers: These are more suitable for smaller-scale operations or for cans that require special handling. Single head seamers focus on sealing one can at a time, providing high precision but at a lower output rate compared to rotary seamers.

- Double Seamers: Double seamers are designed to create a double seam, which involves folding the can’s lid and body together twice to ensure a hermetic seal. This type of seamer is widely used for its reliability and effectiveness in sealing.

- Vacuum Seamers: These machines are specialized for creating a vacuum inside the can before seaming. They are particularly useful for products that require a high degree of preservation, as the vacuum helps prevent spoilage.

- Automatic Seamer with Fillers: Some machines integrate filling and seaming in one system. These machines first fill the can with the product and then immediately seam it, making the process more efficient and reducing the risk of contamination.

- Steam Flow Seamers: These seamers use steam to heat the can during the seaming process. The steam helps to create a better seal by softening the can’s material slightly.

Each of these machines has its own set of advantages and is chosen based on the specific requirements of the production line, such as the type of product being canned, the desired speed of production, and the size and shape of the cans.

Emballge Packaging: Revolutionizing Canning with State-of-the-Art Seamer Machines

Welcome to Emballge Packaging, where innovation meets efficiency in the world of canning. As a leading manufacturer of professional can seamer machines, we are dedicated to providing solutions that blend cutting-edge technology with unwavering reliability.

Unmatched Quality and Precision: Our can seamer machines are designed to ensure the highest level of precision and quality. Whether you are dealing with food products, beverages, or any other canned goods, our machines deliver a perfect seal every time, preserving freshness and extending shelf life.

Tailored to Your Needs: We understand that every production line is unique. That’s why Emballge Packaging offers a range of seamer machines, from high-speed rotary seamers to precision single-head seamers. Our team works closely with you to identify the best fit for your specific requirements, ensuring optimal performance and efficiency.

Innovative Technology: At the heart of our machines lies innovative technology. We are constantly exploring new ways to enhance our products, incorporating features like vacuum seaming and steam flow technology. This commitment to innovation ensures that our clients are always at the forefront of the canning industry.

Eco-Friendly Solutions: In today’s world, sustainability is key. Our machines are designed with the environment in mind, promoting eco-friendly practices through energy-efficient operation and reduced waste.

Unparalleled Customer Support: Emballge Packaging doesn’t just sell machines; we build partnerships. Our expert team is always ready to provide support, from initial consultation to ongoing maintenance and upgrades.

Global Reach, Local Service: With a global presence and a commitment to local service, we ensure that no matter where you are, you have access to the best in can seaming technology and support.

Join the Emballge Family: By choosing Emballge Packaging, you’re not just getting a machine; you’re gaining a partner in your success. Experience the difference in quality, efficiency, and service with Emballge Packaging, where your canning needs are our top priority.